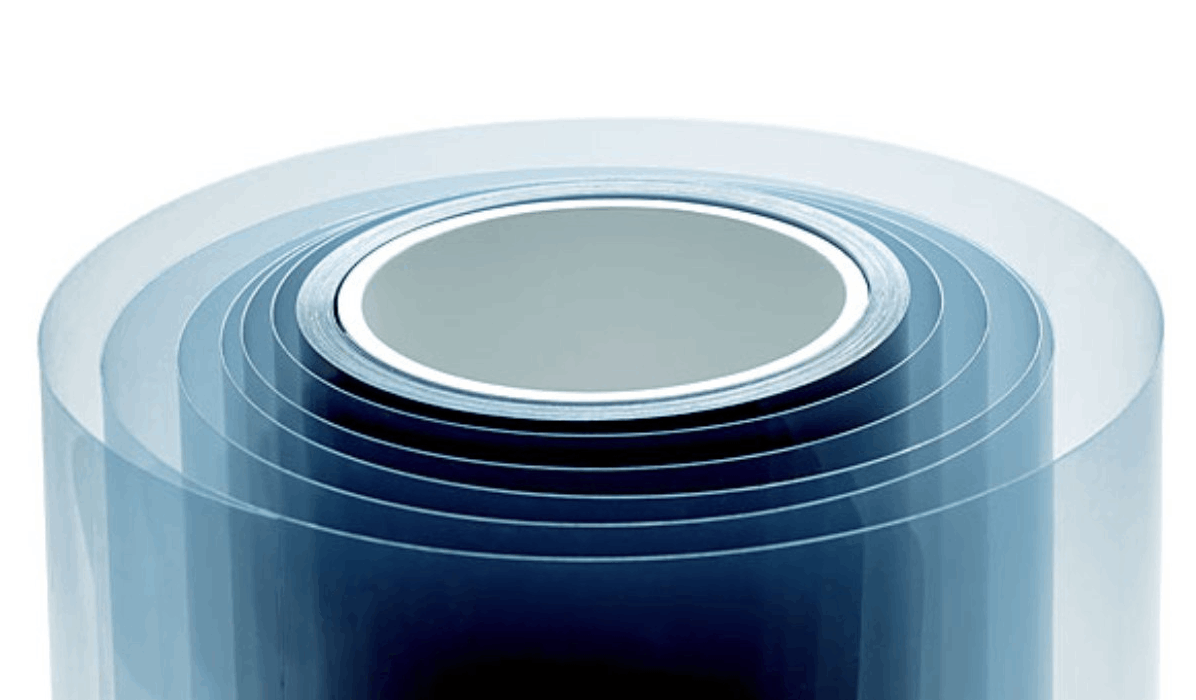

APET SHEETS (Amorphous PET)

These are virgin grade premium quality monolayer PET sheets. Applications include general packaging, dairy products, thermoforming & food packaging applications. They are also suitable for different printing techniques like UV, offset & flexo printing.

ARA PET SHEETS (APET / RPET / APET)

It is a co-extruded three layer structure where in RPET is used in middle layer ,& APET is used in outer & inner layer. Applications include thermoforming & vacuum forming of blister packing & clamshells for packaging of food, pharma, consumer & electronics products.

RPET SHEETS (Recycled PET)

RPET is a monolayer sheet which is produced using 100% post consumer washed PET flakes. Its features include excellent transparency, better barrier properties & stretchability, zero migration into packed food, etc. It is an economical replacement of PVC sheets for thermoforming & blister packaging, with a wide range of applications in both institutional & commercial display packing.

It is a safe and sustainable packaging solution to preserve environment.

GAG PET SHEETS (PETG / APET / PETG)

It is a co-extruded three layer sheet using APET in middle layer & GPET in outer & inner layer. As compared to APET sheets, GAG PET sheets have better printing & adhesion properties, thanks to PETG surface layers. It supports easy vacuum forming & bending with heat process, & allows operations like punching. It is best suited for interior decoration of stores, signboards/ displays, POP advertisement, etc.

PETG SHEETS (Glycol Modified PET)

Monolayer PETG sheet has outstanding thermoforming characteristics for applications that require deep draws & complex die cuts without sacrificing structural integrity.Further,PETG sheets do not require pre-drying before thermoforming process. It is widely used for signs & graphic holders,POP & advertisement display product & table top displays.

GRG PET SHEETS (PETG / RPET / PETG)

GRG PET sheet has a co-extruded three layer structure with RPET in middle layer, & PETG in outer layers.